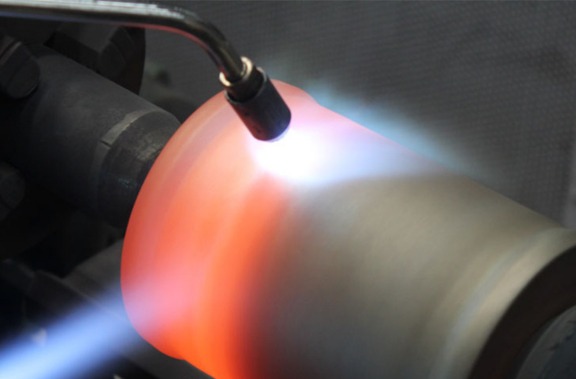

A coating formed by deposition of fine molten or Semi-molten particles onto a substrate

- The material to be deposited is introduced into an energy source causing it to either melt or plastically deform

- The molten / semi-molten material is then accelerated using the stream of pressurized gas

- Material to be sprayed can be in powder or wire form depending on the process

Advantages of Thermal Spray Coating

- Thin film coatings ( 100 to 500 microns) that can impart an array of superficial properties like wear, corrosion, and erosion resistance.

- Maximum compatibility with various substrate materials.

- Properties of substrate materials are not affected and therefore design strength is maintained.

- Performance of the component can be enhanced significantly

- Components with coatings can be easily repaired for reuse