Plasmatron provides customized weld overlay solutions intended to improve the performance and life of critical industrial components. Weld overlays consist of a layer of wear or corrosion resistant material applied over a base metal to improve functionality and durability. Weld overlays are essential in Oil & Gas, Power generation, Steel, Mining, and Manufacturing industries, where components experience harsh operating conditions.

One of the main technologies employed is Gas Tungsten Arc Welding (GTAW) or TIG welding. The process is suitable for applications requiring precision overlay where a good finish and tight metallurgical bond are vital. GTAW provides good control of heat input as well as weld quality and is appropriate for complex components where accuracy and consistency are demanded.

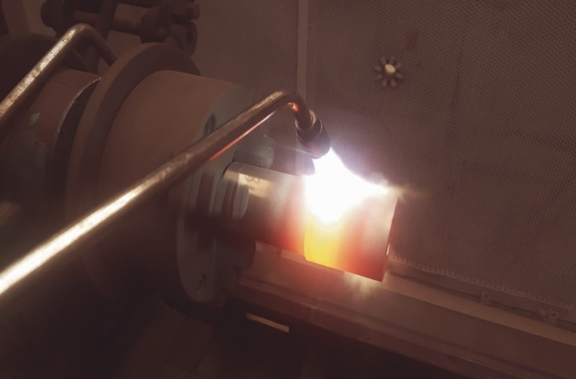

For use in applications requiring high hardness and wear resistance, Plasmatron offers Plasma Transferred Arc Welding (PTAW). This process is an automated, high-energy method for producing dense, metallurgically bonded overlays with low dilution. PTAW is extensively applied in coating pump shafts, plungers, and other high-wear components, offering long service life with low maintenance costs.

Another successful solution is Spray & Fuse, which involves a two-step thermal spraying with subsequent fusing of the deposited material by heating it with a torch or furnace. The procedure yields a smooth, hard, and well-bonded coating that withstands wear, corrosion, and impact. Spray & Fuse is widely used on parts such as rollers, bushings, and seal surfaces where a tough and long-lasting coating is required.

Plasmatron India’s weld overlay services are designed to achieve the highest quality and performance requirements. Through the integration of state-of-the-art technology, expert craftsmanship, and rigorous quality control, the company provides assured protection for mission critical equipment offering long-term cost benefits and enhanced operational uptime for its customers.