Continuous Galvanizing Line

Problem

The purpose of the Continuous Galvanizing Line (CGL) is to apply a coat of zinc onto the surface of steel sheets in an effort to increase their corrosion resistance. This process is classified as Hot Galvanizing and Cold Galvanizing. Molten Zinc and Aluminium are very reactive and corrosive in nature. Molten zinc reacts with insoluble iron particles in the bath to form dross which is a hard crystalline residue. If such a residue is formed on the surface of the process rolls (Sink Roll, Stabilizer Roll or Correction Roll), it leads to inclusion in the galvanized sheet and even worse, it could lead to defects in the end product.

Solution

GALDEX DB13 and PIC C59 Coating

We offer GALDEX DB13 coating on sink and stabilizer rolls, delivering a dense and homogeneous coating that is non-reactive to molten aluminum and zinc. The Sink and Stabilizer rolls coating is deposited through the HP-HVOF process and sealed with an indigenously developed ceramic sealant. This prevents the formation of dross over the barrel surface, thereby protecting the galvanized sheet from surface damage.

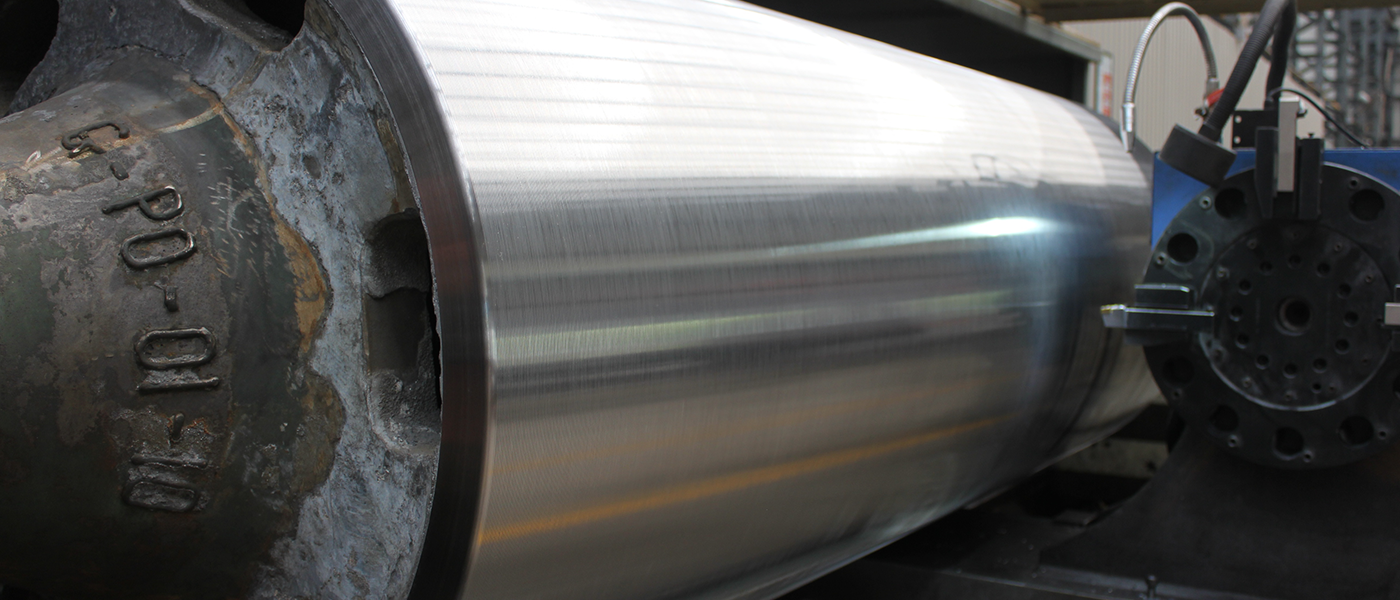

GALDEX DB13 restricts the diffusion of zinc and aluminum through the coating, further enhancing coating life and performance. The non-reactivity and anti-wetting properties of Sink and Stabilizer Rolls Coating prevent zinc adhesion on the coated barrel surface, making periodic cleaning and maintenance significantly easier. GALDEX DB13-coated rolls have demonstrated 5–8x better operational life without corrosive pitting or dross formation compared to uncoated SS 316L rolls, and 3–5x better operational life compared to conventional tungsten carbide-coated rolls. We supply fully coated sink and stabilizer rolls as per customer specifications, up to a maximum diameter of 800 mm. We also refurbish these rolls by stripping damaged coatings and machining precision micro-grooves prior to recoating, which play a critical role in coating performance. These micro-grooves are machined to perfection on our heavy-duty, calibrated CNC machines.

We have also indigenously developed PIC C59 coated Sink roll and Stabilizer roll sleeves to sustain the similar extreme operating conditions as encountered by Sink roll and Stabilizer rolls. These sleeves are completely manufactured in-house as per customer specification. The coating is deposited through a proprietary process under tightly controlled conditions. Every stage of manufacturing—from machining helical grooves to post-coating finishing—is executed with precision. Our PIC C59-coated sleeves have been successfully tested in operation and have proven to increase operational life by 3–5x compared to conventional stellite-coated sleeves, while also offering exceptional resistance to impact and abnormal vibrations.

| Coating Properties | GALDEX DB13 | PIC C59 |

|---|---|---|

| Process | HVOF | Proprietary |

| Bonding | Mechanical | Metallurgical |

| Micro Hardness | 700 – 900 HV0.3 | 850 – 1000 HV0.3 |

| Coating Application | Molten Metal Abrasion and Corrosion Resistance | Molten Metal Abrasion Resistance |

| Max Temperature | < 850°C | < 850°C |

| Finish Coating Thickness | 150 to 180 µm | 0.8 to 1.5 mm |

Plasmatron is a Reliable Surface Engineering Partner Providing Sink Rolls Coating services in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam, India

Plasmatron is a Reliable Surface Engineering Partner Providing Stabilizer Rolls Coating services in Mumbai, Navi Mumbai, Thane, Agra, Ahmedabad, Ahmednagar, Ajmer, Amravati, Amritsar, Aurangabad, Bangalore, Beed, Belgaum, Bharuch, Bhavnagar, Bhopal, Bhubaneswar, Calicut, Chandigarh, Chandrapur, Chennai, Coimbatore, Cuttack, Daman, Delhi, Dhule, Ernakulam, Erode, Gangtok, Ghaziabad, Goa, Hubli, Hyderabad, Indore, Jaipur, Jalgaon, Jamshedpur, Jodhpur, Kolhapur, Kolkata, Lucknow, Ludhiana, Madurai, Mysore, Nagpur, Nashik, Noida, Patna, Pondicherry, Pune, Raipur, Rajkot, Salem, Satara, Secunderabad, Shimla, Sikkim, Silvassa, Solapur, Srinagar, Surat, Udaipur, Vadodara, Valsad, Vellore, Vijayawada, Visakhapatnam, India