Steel

Overview

The steel industry is one of the essential industries for the development of any community. It not only symbolizes growth and development but also forms a base for many new emerging industries that would otherwise not have been established without steel. The conversion of iron ore or steel scrap to finished product can be routed through three different methods viz Integrated steel production,

Secondary processing and Direct reduction. In all three conversion processes, the

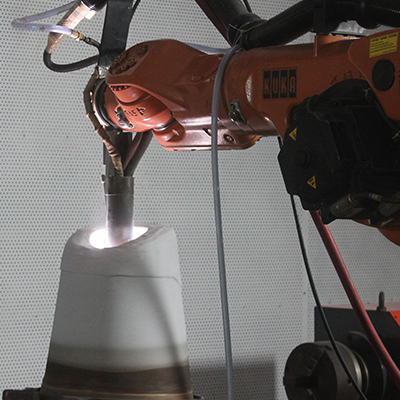

critical components in the line are subjected to varying extreme operating conditions such as high temperature wear, abrasion, erosion, galvanic corrosion etc. A wide range of Thermal spray coating options exists to counter these harsh operating environments, thereby increasing operational life and reducing downtime costs.

Different coating materials include ceramic, carbide, cermet and composites. Thermal spray coatings are also known to replace many alternative surface treatment methods such as Nitriding, Hard chrome plating, PU coating etc., particularly in applications requiring Wear and Corrosion Protection. Wear and Corrosion Resistant Coatings for Steel offer unmatched protection against harsh industrial environments, ensuring durability, reliability, and extended service life.

High Temperature Coatings for Steel are essential in protecting components exposed to extreme thermal conditions, ensuring improved durability and performance in steel production environments. These coatings help resist oxidation, thermal fatigue, and high-temperature wear.