Mud Rotors

Mud Rotors

Problem

Solution

PIC DC09 Coating

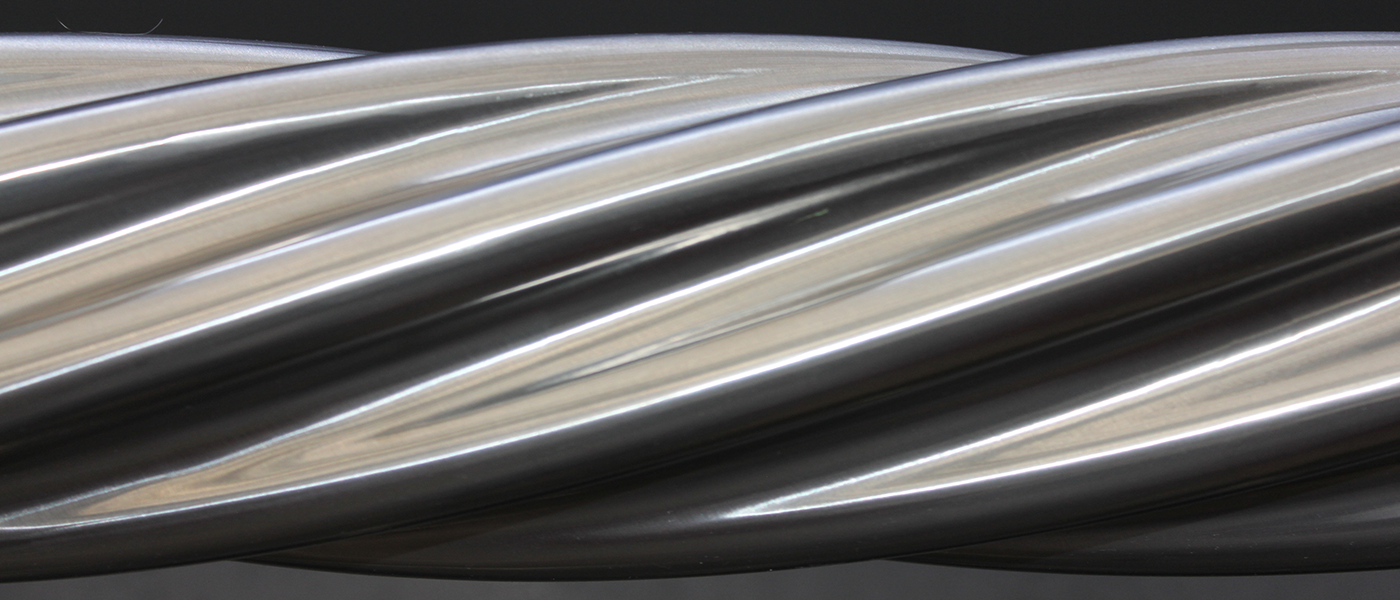

Our PIC DC09 coated mud rotors can withstand extreme abrasive and corrosive environments and offer exceptional operational life and performance. The coating is applied with robotic controlled HP-HVOF process in repeated passes that produces a dense and homogeneous coating. We offer complete repair and refurbished tungsten carbide coated rotors and conversion of hard chrome plated rotors to Tungsten Carbide Coated rotors. We have indigenously developed a complete set of procedures with our internal research and technical expertise combined with highly skilled man force. Our PIC DC09 coated mud motor rotors offer up to 5 – 7x operational life as compared to traditionally hard chrome plated rotors.

The coated rotors are impregnated with indigenously developed ceramic sealant and cured to fill the inherent porosity. The rotor surface is then ground and polished to achieve mirror surface finish. The contour profiles and diameters are maintained as per customer specifications and verified by matching with template. We have specialized measuring and monitoring instruments dedicated for inspection of rotors. We have in-house capabilities to completely repair and refurbish rotors up to a maximum length of 8 meters.

| Coating Properties | PIC DC09 |

|---|---|

| Micro Hardness | 1100 - 1400 HV0.3 |

| Porosity | < 0.8% |

| Bond Strength | > 10000 Psi |

| Abrasion Resistance | Excellent |

| Corrosion Resistance | Very Good |

| Max Temperature | < 450°C |

| Finish Coating Thickness | 180 to 200 µm |

| Surface Finish | < 0.4 Ra µm |