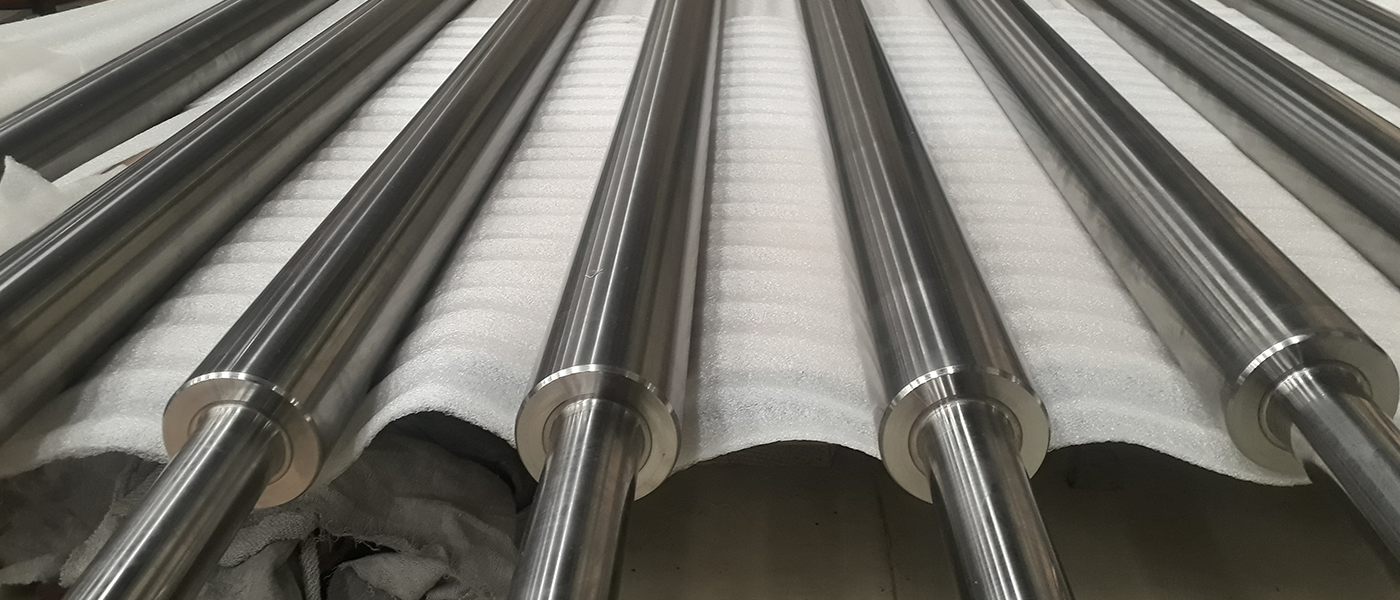

Piston Rods

Piston Rods

PIC DC Range of Coatings

We have been actively involved in providing specialized coating solutions for compressor piston rods to combat wear, abrasion and corrosion. The coatings are applied with HP-HVOF process that produces a dense and homogeneous coating with very strong mechanical adhesion to the rod surface. The coatings are ground and super-finished, further enhancing the sliding properties and reducing wear of mating seal parts. Our PIC DC range of coating solutions prove to be the best replacement for hard chrome plated piston rods and improves the operational life by 5 – 8x.

We refurbish piston rods which are previously nitrided, hard chrome plated or tungsten carbide coated. We have in-house setup for complete manufacturing of coated piston rods ranging from 12 to 120 inches in length.

| Coating Properties | PIC DC08 | PIC DC09 | PIC DC12 |

|---|---|---|---|

| Micro Hardness (HV0.3) | 1100 - 1400 | 1100 - 1400 | 800 - 1100 |

| Abrasion Resistance | Excellent | Excellent | Good |

| Corrosion Resistance | Good | Very Good | Excellent |

| Max Temperature | < 450°C | < 450°C | < 850°C |

| Bond Strength | >10000 Psi | ||

| Finish Coating Thickness | 150 to 200 µm | ||

| Surface Finish | < 0.4 Ra µm | ||